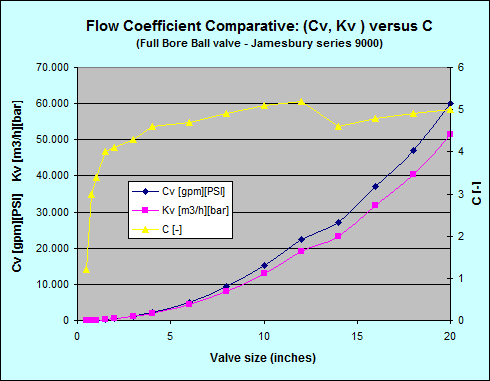

Calculate the orifice size of your valve. With the flow coefficients capacities of valves at different sizes types and manufacturers can be compared.

Effects Of Varying Orifice Diameter And Reynolds Number On

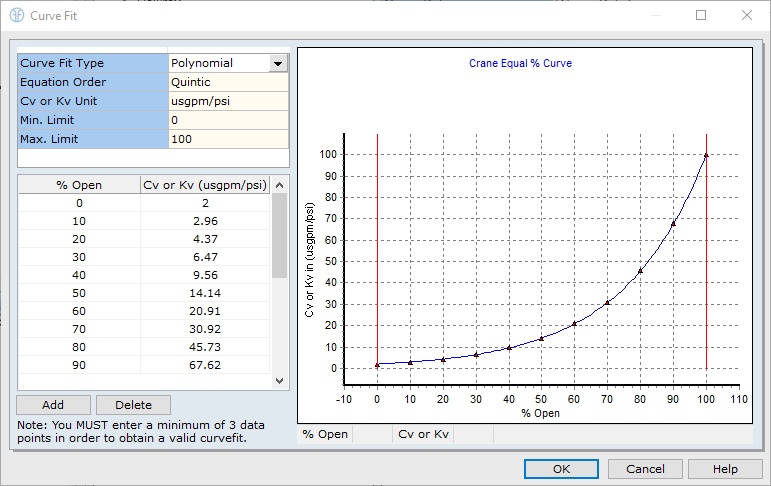

Cv vs orifice size. Upstream pressure is 100 psig downstream to atmosphere. Online calculator to quickly determine valve and orifice cv kvs values for air. Includes 53 different calculations. The flow coefficients are in general determined experimentally and express the. The medium is 70º f methane gas sg554 and the desired flow range is up to 600 scfh. Cv 600 x 554 x 530 816 x 1147 1098 the cv value at which 600 scfh of methane will flow under the above conditions is.

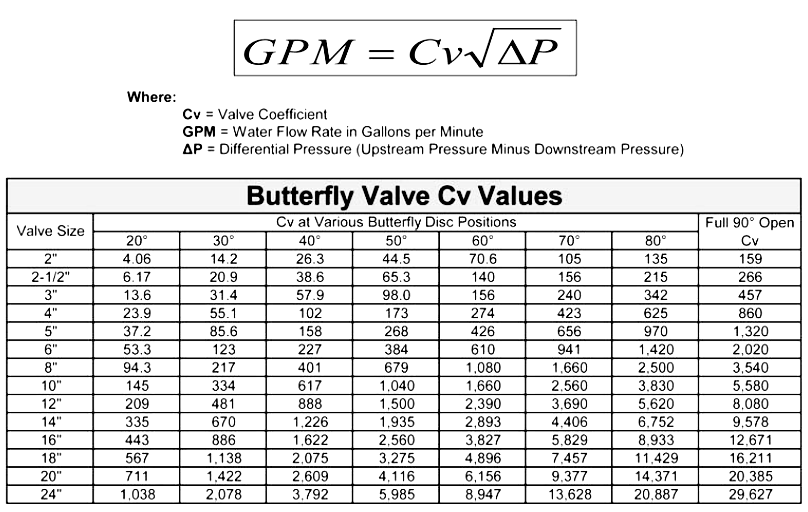

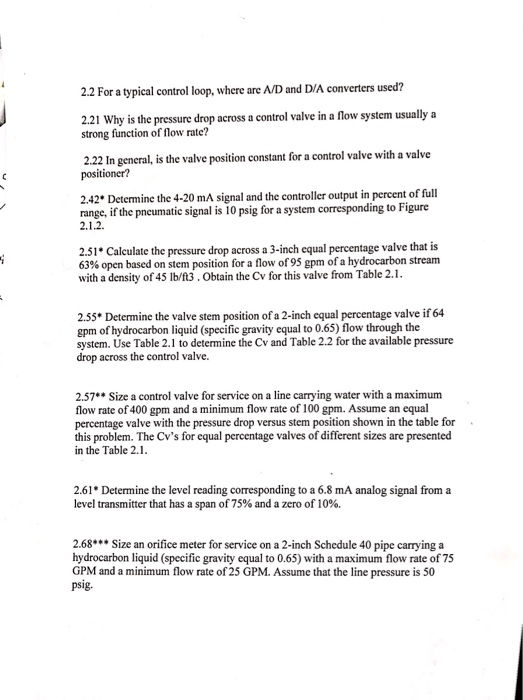

This article demonstrates how to convert between these two parameters when performing functions such as selecting a valve with an equivalent pressure drop to a given orifice plate. Equations displayed for easy reference. Determine which orifice size should be used for the following application. Orifice sizing principles an orifice meter is a device used for measuring the rate of fluid flow. Flow capacity in imperial units gpm us gallons per minute that a valve will pass for a pressure drop of 1 lbin 2 psi the flow factor kv is also commonly used with capacity in si units. It uses the same principle as a venturi nozzle namely bernoullis principle which says that there is a relationship between the pressure of the fluid and the velocity of the fluid.

The information including any recommendations set forth at this website is offered free of charge and is designed for a variety of audiences. The pressure drop or flow rate through a valve or orifice plate is typically calculated using the a flow coefficient cv or orifice diameter. If the cv factor is the same for both paths there will be about the same pressure loss through each. We are reviewing the status of covid 19 on a daily basis and leveraging our global network of manufacturing and distribution centers to mitigate the impact to our customers. If the cv factors are different there will be a higher loss through the path with lower cv factor. Iso 5167 12003 provides an equation for the orifice discharge coefficient calculation cd as a function of beta ratio reynolds number l1 and l2 where l1 is the distance of the upstream pressure tap from the orifice plate and l2 is the distance of the downstream pressure tap from the orifice plate.

The chart shows the relation between inlet pressure outlet pressure and flow capacity for any orifice or valve passage which has a cv factor of.